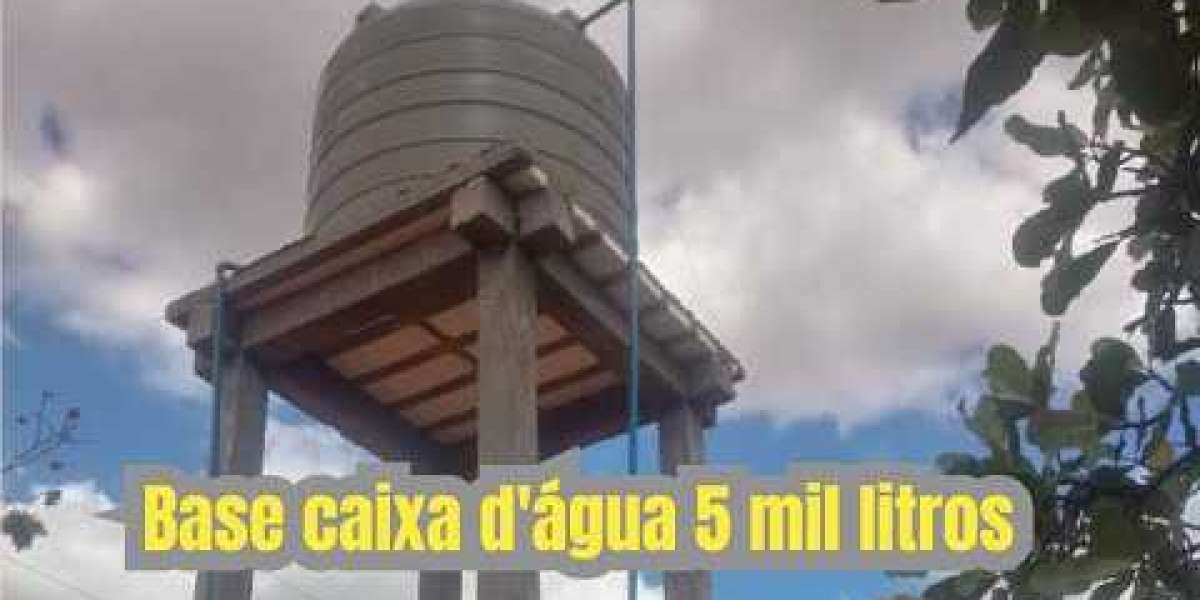

Stainless Steel Water Tank Size

If you neglect to show it off, the protection turnoff switch will do this for you two hours after beginning the equipment. Setting up the machine takes a quantity of clicks, and the equipment does its magic. You can use the programmable timer to ensure sizzling coffee is ready for you within the morning. Read your handbook or ask the manufacturer whether you can place the water tank within the backside rack of your dishwasher. For a thorough descaling, think about using a business descaling answer. Steps usually involve filling the reservoir with the answer, running a brewing cycle, after which running a few extra cycles with clear water.

Best Chicken Waterer Reviews: Fantastic Poultry Hydration Solutions

The drinker/feeder’s progressive design reduces meals wastage because the separate divisions discourage chickens from ‘swiping’ the feed onto the ground. There will be no extra poo, dust, or rain within the feed tray or the ingesting cup as both models are designed to be suspended off the ground. As it has a slimline design, it's excellent for coops that have restricted area. You can hook the waterer onto the mesh of your chicken coop or fix it to a stable wall with the included 4 aluminum brackets. A rooster waterer is a fantastic watering system on your feathered flock.

The wrong paint will fade quicker, cause structural damage, and even trigger your structure to collapse. The operating interval of effectiveness for protective coating should be not lower than 10 years. Protective present goes precisely to these steel areas, where the density of the coating is damaged. It reaches all shadowed areas, gaps, hole areas, stopping the bare steel from staining. It should be famous that in the midst of cathodic polarization native and backside water exhibits sure salt gel that contains insoluble Ca and Mg salts and performs the function of additional coating. For example, penetrating corrosion backside destruction of the tanks, used for oil settling, and flow strains may result in oil spills that pollute the setting. Moreover, there appears the need to substitute the tank bottoms already after 5-6 years of operation, which is difficult, considering the diameter of the underside equal to almost 50 m (for vertical metal tank ).

The wrong paint will fade quicker, cause structural damage, and even trigger your structure to collapse. The operating interval of effectiveness for protective coating should be not lower than 10 years. Protective present goes precisely to these steel areas, where the density of the coating is damaged. It reaches all shadowed areas, gaps, hole areas, stopping the bare steel from staining. It should be famous that in the midst of cathodic polarization native and backside water exhibits sure salt gel that contains insoluble Ca and Mg salts and performs the function of additional coating. For example, penetrating corrosion backside destruction of the tanks, used for oil settling, and flow strains may result in oil spills that pollute the setting. Moreover, there appears the need to substitute the tank bottoms already after 5-6 years of operation, which is difficult, considering the diameter of the underside equal to almost 50 m (for vertical metal tank ).Interior Painting

We understand our purchasers have needs and different tastes, so we take heed to you. We assure you exceptional communication from begin to end of your project. Whether you have a small project or a giant project, interior or exterior, Solution Painting has an answer in your residence or business. On high of skilled work, Solution Painting presents flexible pricing to satisfy your finances. Tankguard HB is a high-build epoxy coating with excessive resistance to a wide range of chemical compounds and caixa d água metálica 15000 litros solvents. It has exceptional corrosion resistance, is surface tolerant and fast drying - tremendously bettering efficiency, It can also be available in a variety of colours. It has a better share of volume solids than both Intertuf sixteen and Rylards Rytex, It can be applied on bare steel or over current coatings.

Often, this includes discussions concerning the surrounding infrastructure and any unique challenges from your project. These components can influence the staffing, scheduling, equipment, and coatings needed for the job. At Markley’s Precision we provide solely The Best paint jobs on the market, which involve sandblasting to a close to white steel blast spec SSPC SP10 or for the most effective blast a white metal SSPC SP5. These tanks are then coated with a coat of zinc wealthy primer, 2 coats of epoxy with an additional stripe coat alongside the welds, and 1 coat of hydroflon polyurethane topcoat. Low high quality paint jobs for a tank typically involve a primary strain wash of the exterior, spot priming areas exhibiting clear corrosion points, then overcoating with a coat of oil based mostly enamel paint. Typically these paint jobs will final 1-5 years with most averaging 1-2 years.

Browse all products

Acting quickly can stop further harm and ensure your water storage remains in high condition. Proper surface preparation adopted by making use of suitable primers and paints will restore the tank’s protection in opposition to corrosive forces. We use state-of-the-art equipment to ensure your job is completed right the first time, saving you trouble and expense within the course of. Premiere Works has a professional group of inside painting contractors and industrial exterior portray professionals that specializes in making commercial facilities look contemporary and new. Often it appears that these tanks have been beforehand coated with a bitumen product or one that was applied earlier than any strict approval was required.

Safety Data Sheets

When working with water, gas, or storage tanks, industrial painting methods must all the time include a cautious review of the protection precautions to safe the job site and keep everybody secure. This consists of portray contractors and any workers that may work in close by areas. You can use one of the best coating/paint merchandise in the world, but if the floor isn't prepared properly before the application, untimely coating failure and substrate steel deterioration is inevitable. Bolted and welded steel tank exteriors are prone to corrosion introduced on by many outside causes. In all circumstances, as quickly as corrosion has began underneath the tank’s protecting coating, the structural integrity of the vessel may be affected and if not corrected, finally compromise the useful lifetime of the tank.